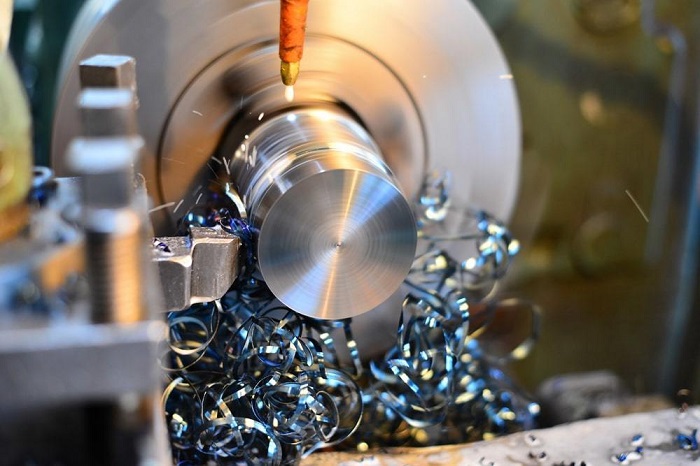

How To Select The Right Precision Tool For Your Manufacturing Needs?

Selecting the right precision tool for your manufacturing needs is crucial for the success of your operation. Factors you should consider include the material being worked on, the accuracy and tolerance required, and the production volume.

Additionally, the type of machining operation, machine tool compatibility, and budget should also be taken into account. To make the best decision, it is recommended to consult with industry experts, analyze your specific requirements, research different options in the market, and check out LOCUS Precision before making any firm decision.

Tips for selecting the right precision tool for your manufacturing needs:

- Inspect the material

Inspecting the material is crucial in selecting the right precision tool for your manufacturing needs. The type of material you will be working with can significantly impact the selection of cutting tools and abrasives.

Some materials may be softer and require a different cutting edge, while others may be harder and require a more robust tool. Evaluating the material you will be working with is crucial to select the right tool. It may involve testing the material’s hardness, strength, and other properties.

- Determine the tolerance level.

Determining the tolerance level is essential in selecting the right precision tool for your manufacturing needs. The tolerance level refers to the amount of deviation allowed in the dimensions of the finished product.

For example, a high tolerance level would allow for more variation in the dimensions, while a low tolerance level would require a higher degree of accuracy. When selecting a precision tool, it is essential to consider the tolerance level needed for the finished product. It will help ensure that your chosen tool can meet your manufacturing requirements and produce the desired outcome.

- Consider the budget

Consideration of your budget is crucial in selecting the right precision tool for your manufacturing needs. High-end precision tools can be expensive but may provide better results and a longer lifespan. On the other hand, lower-priced tools may not meet your manufacturing requirements or may have a shorter lifespan, leading to additional costs in the long run.

It is important to balance cost and quality to ensure you get the best value for your investment. When selecting a precision tool, consider the tool’s budget and the potential maintenance, replacement, and downtime costs.

- Evaluate the production volume.

Evaluating the production volume is essential in selecting the right precision tool for your manufacturing needs. The production volume refers to the number of manufactured parts and the required production rate. When selecting a precision tool, it is vital to consider the production volume to determine the tool type and size best suited for your needs.